USACH ID/OD Solutions

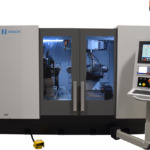

USACH 5 axis ID/OD grinder platforms meet the needs of advanced material manufacturers. These USACH machine platforms are ideally suited for high precision grinding applications that require a high level of flexibility. With their consolidated functionality these machines are able to extend the typical standard range of grinding machines thus allowing for complex automated processes in single setups combining ID, OD, Bevel, Face, Radius, and small feature grinding including allowing to use roughing and finishing wheels to achieve higher surface finishes and consistent part quality. These USACH platforms contribute significantly to the manufacturer’ s bottom line. With their streamlined efficiencies and unique capabilities, the USACH custom grinder positions the manufacturer to support growth in its targeted industries and opens the door for innovation in advanced material markets.

Choose from multiple USACH models for application-specific requirements:

USACH ID/OD GRINDING SOLUTIONS

USACH 100

• Max Part Diameter: 560 mm (22”)

• X-Axis Travel: 500 mm (19.7”)

• Z-Axis Travel: 450 mm (17.7”)

USACH 100 XL

• Max Part Diameter: 1000 mm (40”)

• X-Axis Travel: 600 mm (23.6”)

• Z-Axis Travel: 750 mm (29.5”)

Features:

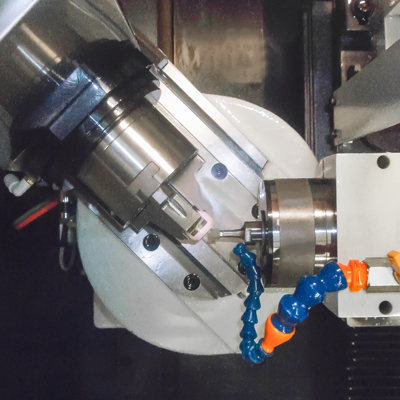

- MULTI-SPINDLE TECHNOLOGY

Industry leading hydrostatic B1/B2 axes swiveling technology for both workhead and wheelhead side for enhanced machine flexibility and to support fully integrated 5-Axis control architecture to achieve all grinding operation under optimal grinding conditions. - TOOL CHANGE SPINDLE (ATC)

For speeds up to 60,000 rpm mounted on horizontal or vertical axis - VERTICAL Y AXIS IDEALLY SUITED FOR:

• Face grinding of stationary Parts

• Grooves and slots on face and OD

• Off-center hole drilling and tapping

• Gaging of off-center features

• Automatic Part Centering - CENTER DRIVE SYSTEM

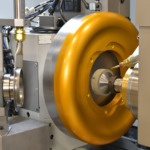

Solutions allow to grind ID’s, faces and OD’s on parts from both sides in sub-micron tolerances. The grinding surfaces are positioned to the grinding spindles using the two CNC B-Axes. - SHOE GRINDING WITH RADIUS DRESSER

For precision bearing race grinding the platform is configured in the C execution and equipped with high precision radius dresser using single point diamonds or driven rotary disc.

Options:

- Software & Controls

- Workheads

- Center Drive

- Tailstocks

- Turrets

- Spindles

- Dressers

- B Axis and B1 Axis

- Auxiliary Axes

- Gaging and Pro

- Automation

- ID Option for OD Grinders

- FANUC 32 Series

- FANUC 0iF Plus

- Mitsubishi M70V

- Siemens 840 D

With its multi axis interpolation capabilities, USACH provides unmatched grinding solutions for sphere and mirror grinding. Complex alumina applications are processed with several spindles and a variety of tools automatically change to the grinding spindles. Combining processes in one machine with multiple spindles provide customers with unique solutions that complete parts in one setup to the highest qualities and accuracies.